Recognizing the Fundamentals of Welding Inspection to Ensure Quality and Safety

In the world of contemporary design, welding evaluation stands as a cornerstone for making certain both the quality and safety and security of structural developments. What are the subtleties of these evaluation approaches that make them important for maintaining structural honesty?

Importance of Welding Evaluation

In the world of industrial fabrication, the importance of welding examination can not be overemphasized. Welding inspection plays a critical duty in making sure the honesty, safety, and longevity of welded structures. Given the diverse applications of welding in industries such as construction, automobile, aerospace, and shipbuilding, the requirement for strict high quality control procedures is extremely important. Correct inspection ensures that welds meet defined criteria and codes, which is crucial for preventing architectural failings that might cause disastrous repercussions.

The process of welding inherently entails complicated variables, including temperature level, product residential properties, and environmental problems, every one of which can influence the top quality of the weld. A detailed assessment identifies issues such as fractures, porosity, and incomplete blend, which can jeopardize the toughness and dependability of the weld. By spotting these concerns early, restorative actions can be taken, consequently decreasing the threat of failure and linked expenses.

Additionally, welding assessment adds to regulative compliance, as lots of industries are regulated by strict security criteria and guidelines. Failing to stick to these guidelines can result in legal responsibilities and monetary fines. Eventually, welding inspection not only safeguards physical frameworks but also secures human lives and upholds industry track records.

Trick Welding Inspection Techniques

Although welding assessment is essential to making certain the top quality and security of welded frameworks, it is the details techniques employed that determine the performance of the assessment process. Trick welding assessment techniques can be broadly classified into non-destructive screening (NDT) and harmful testing.

Ultrasonic and radiographic screening are much more advanced strategies that allow assessors to examine the internal honesty of the weld. Ultrasonic testing makes use of high-frequency acoustic waves to detect stoppages, while radiographic testing uses X-rays or gamma rays to create a photo of the weld's interior. Magnetic fragment testing and fluid penetrant testing are surface area evaluation approaches used to situate surface and near-surface problems. In contrast, harmful testing techniques entail physically cutting the weld or damaging to assess its mechanical residential properties. These comprehensive assessment methods make sure that welds fulfill industry requirements and safety and security requirements, consequently making certain structural stability and efficiency.

Role of Licensed Examiners

Licensed examiners play an essential duty in the welding examination procedure, making certain that all welds abide by rigid sector criteria and safety and security laws. Their knowledge is vital in determining flaws or irregularities that may compromise the structural integrity of a weld. By meticulously examining each weld, licensed assessors aid stop prospective failures that could lead to costly fixings or unsafe crashes.

To come to be licensed, examiners must undertake extensive training and testing, which familiarizes them with numerous welding methods, materials, and screening techniques. This extensive knowledge Welding Inspection Madison permits them to assess weld quality properly and make notified judgments about their safety and security and dependability. Additionally, qualified examiners are competent in analyzing requirements and blueprints, ensuring that the welding work aligns with the job's design needs.

An essential component of their role is to document their searchings for thoroughly, supplying a detailed record of the examination process. This paperwork is crucial for traceability and responsibility, working as an official record of conformity with industry standards. Licensed assessors also play a crucial duty in helping with communication in between task stakeholders, providing insights and referrals to improve welding methods and end results. Their payment is essential in preserving high degrees of top quality and safety and security in welding operations.

Tools Used in Welding Inspection

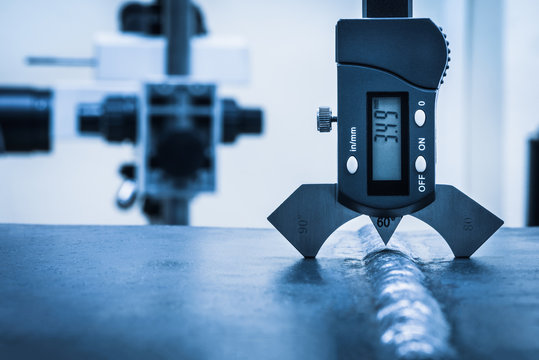

Welding inspectors count on a selection of specialized devices to do their duties effectively, making certain each weld fulfills the needed requirements. Among these devices, visual evaluation help like multiplying glasses and mirrors are essential, allowing assessors to carefully analyze welds for surface issues such as fractures, porosity, and undercut. Calipers and fillet weld gauges are essential for gauging weld dimensions to verify compliance with layout specs.

Advanced tools prolong past aesthetic aids, consisting of non-destructive testing (NDT) tools. Ultrasonic testing tools are essential in discovering subsurface flaws, making use our website of acoustic waves to disclose internal stoppages without jeopardizing the weld's integrity. Likewise, radiographic testing utilizes X-rays or gamma rays to record pictures of a weld's inside, highlighting potential issues.

Magnetic particle testing is an additional crucial device, particularly for finding surface area and near-surface gaps browse around here in ferromagnetic products. By applying electromagnetic fields and ferrous fragments, assessors can recognize defects that may or else be invisible.

Dye penetrant assessment is usually used for non-ferrous materials, supplying a contrast-enhanced aesthetic check for surface-breaking problems. Welding Inspection Madison. Together, these devices make it possible for welding inspectors to comprehensively examine weld top quality, making certain security and reliability in various applications across industries

Ensuring Structural Stability

Welding procedures have to follow recognized standards and codes, such as those defined by the American Welding Society (AWS) or the International Company for Standardization (ISO) These guidelines ensure that the welds can stand up to ecological elements and functional anxieties. Qualified and accredited welders play an important role in this process, as their knowledge makes sure that techniques are used correctly, decreasing problems such as splits, porosity, and incomplete combination.

Post-weld assessment is an additional essential component of confirming structural stability. These inspections confirm that the welds fulfill the needed high quality requirements, giving guarantee of their durability and reliability.

Conclusion

The fundamentals of welding inspection are essential for keeping the high quality and security of welded structures. By implementing vital examination approaches, such as aesthetic evaluations and non-destructive testing, possible flaws that might compromise structural stability are determined. Certified assessors are important in making sure compliance with industry criteria and efficient communication amongst stakeholders. Using specialized tools better improves the evaluation process, ultimately guarding human lives and extending the lifespan of bonded buildings.

Welding assessment plays a crucial duty in ensuring the stability, safety, and long life of welded frameworks.Although welding evaluation is important to guaranteeing the high quality and safety of welded frameworks, it is the details methods utilized that determine the efficiency of the assessment procedure. Secret welding examination methods can be extensively classified right into non-destructive testing (NDT) and damaging screening.Qualified inspectors play a critical function in the welding examination procedure, ensuring that all welds conform with rigorous industry standards and security guidelines.The principles of welding inspection are important for preserving the high quality and security of bonded frameworks.